Summary: Selecting the right switching solution requires technical clarity and application awareness. This guide explains critical evaluation factors, from electrical ratings to safety compliance, helping engineers and procurement teams make informed decisions. It also highlights how general purpose micro switches align with industrial requirements and why standards such as switch IEC/EN 60947 play a decisive role in ensuring operational safety and long-term reliability.

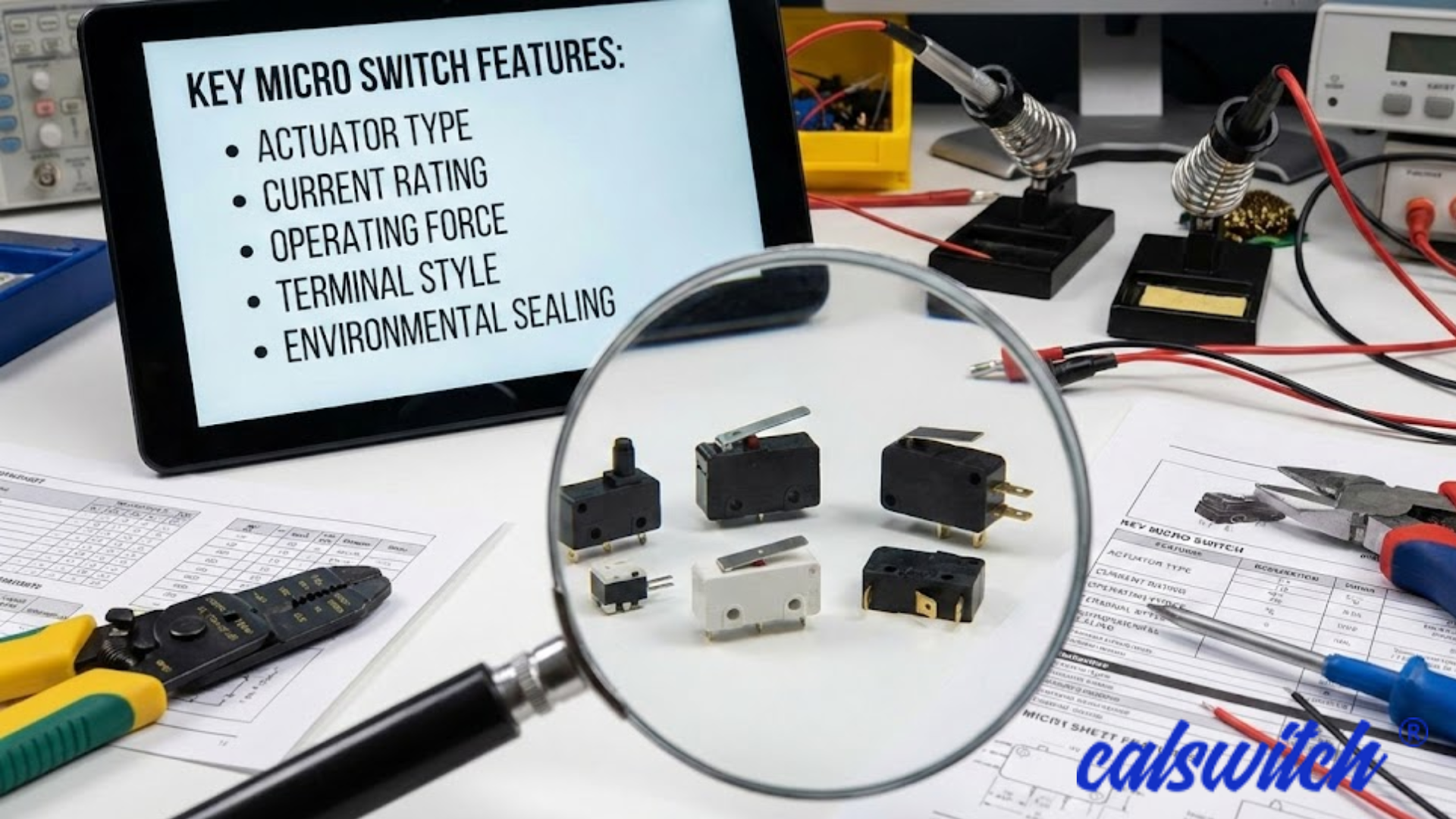

Micro switches form the backbone of countless industrial and commercial systems, enabling precise control and dependable actuation. While the market offers a wide selection, not every option suits every application. Understanding construction quality, performance metrics, and compliance expectations allows buyers to reduce downtime, manage risk, and improve system efficiency. This article explores the most important features to assess before finalizing a switch selection.

Electrical Ratings and Load Capacity

The electrical ratings specify the performance of a switch in the actual operating conditions. Voltage, current, and contact resistance are the factors that directly affect safety and life. When there is an imbalance between system load and switch rating, it tends to wear off or break down too soon. These values are usually checked by the engineer during the advanced stages of selection in order to be aligned with the control circuits and power requirements. Proper ratings enhance stability of performance, as well as reduce disruptions in maintenance.

Mechanical Life and Durability

Durability reflects how well a switch withstands repeated actuation. Mechanical life ratings give the number of cycles that a switch undertakes before it experiences degradation. Switches that are used in high-cycle environments such as automated machinery and control panels offer a long service life. Robust housings, hardened actuators, and fine-tuned springs produce long-term dependability through the harsh industrial environments.

Actuation Force and Response Accuracy

Actuation force determines how much pressure triggers contact movement. Applications requiring precision, such as limit detection or safety interlocks, rely on consistent actuation characteristics. Too much force results in mechanical stress, whereas too little results in false triggering. To ensure the accuracy of operations, designers tend to choose general-purpose micro switches between responsiveness and tactile stability.

Environmental Resistance and Sealing

Switch performance is influenced by exposure to the environment. Unprotected components are deteriorated by dust, moisture, oils, and vibration. Sealed enclosures and protective materials enhance life span in manufacturing floors and lifts as well as process control systems. The selection of switches that have relevant ingress protection provides the stability of performance even in the case of harsh operating conditions.

Compliance with Safety Standards

The safety standards confirm the appropriateness of the product to be used in the industry. Certification against switch IEC/EN 60947 confirms that a switch meets established requirements for low-voltage control and protection devices. Compliance will minimize regulatory risk and provide safe system integration. Certified components are of great interest to manufacturers and OEMs in order to make approvals easier and remain globally compatible.

Contact Configuration and Circuit Design

The contact arrangements define the interaction between a switch and control logic. Different operational requirements are supported by normally open, normally closed, and changeover contacts. The appropriate choice of configuration enhances reliability in the signals and also makes the circuit design easier. Switches can be adjusted to various platforms without redesigning the underlying systems, as flexible options permit engineers to flexibly adjust switches.

Mounting Style and Installation Flexibility

Mounting compatibility affects the speed at which one can install and access the maintenance. They are panel mount, side mount, and PCB mount to accommodate different equipment layouts. The small size allows it to be implemented in assemblies that are space-constrained, and the standardized mounting size can be easily replaced. The mounting features have been well designed to minimize installation error and enhance efficiency in the services.

Material Quality and Contact Composition

Electrical conductivity and wear resistance depend on the choice of materials. Contacts made of silver alloy are stable in current transfer, and special coatings enhance corrosion. Mechanical strength and thermal stability are also dependent on housing materials. Good materials help to achieve predictability in performance through varying cycles of operations.

Consistency Across Applications

The ability of general-purpose micro switches to be versatile is still a survival feature. Their flexibility in terms of manufacturing machinery, game consoles, elevators, and control boards minimizes the complexity of inventory. The compatibility of performance among other applications makes sourcing easier and the quality of operations similar across the board.

Standards Alignment for Global Use

International business usually involves meeting standards dictated by the international standard. Compliance with switch IEC/EN 60947 favors cross-border equipment implementation and compliance. Strict levels of compliance also enhance compatibility with other interoperable certified components, which enhance the general reliability of the system.

Supplier Reliability and Technical Support

The performance of the product goes beyond physical specifications. Trusted suppliers will make documentation, testing information, and guidance of use available. Availability of knowledgeable technical support enhances the ease of troubleshooting as well as shortens project schedules. The uncertainty in the operations is minimized by having long-term relationships with suppliers whom they trust.

Response Consistency and Contact Stability

Uninterrupted power supply guarantees uniform system operation. Contact bouncing or signal drop in variation influences the accuracy of control, particularly in automation and sensing. Micro switches are well engineered and remain consistent in contact capability throughout multiple operations, which facilitates consistent signal delivery and simplifies diagnostic procedures in commissioning and maintenance of the system.

Thermal Performance Under Continuous Operation

Changes in temperature have an impact on material growth, contact resistance, and spring tension. Continuous operation switches are those switches that can be used to ensure performance integrity within a defined temperature range. Thermal stability is needed more, especially in enclosed panels and industrial machinery where heat dissipation is minimal. Adequate thermal tolerance is a factor that leads to service life and safety of operation.

Noise Reduction and Signal Integrity

Sensitive control circuits and monitoring systems are interfered with by electrical noise. The switches used are of high quality to reduce chatter and transitory signals when actuating. Snap-action features are also under control, which enhances the quality of the signal and promotes precise feedback and purer data collection. The decreased noise makes the integration with the modern PLCs and digital control architectures less challenging.

Maintenance Predictability and Lifecycle Planning

The wear patterns are predictable and enable the teams to plan the maintenance cycle. Switches whose lifecycle information is recorded also allow implementing proactive replacement policies instead of reactive ones. This will reduce unexpected downtime and enable the control of costs in long-term operation, especially in industrial high-duty processes.

Conclusion

Choosing the right switch involves more than comparing specifications. Evaluating performance metrics, environmental resistance, and certification ensures dependable operation across applications. When engineers prioritize general purpose micro switches that meet switch IEC/EN 60947 standards, they support safety, efficiency, and scalability. CalSwitch delivers proven switching solutions backed by industry expertise and trusted global brands.

Explore reliable switching solutions built for performance, partner with CalSwitch to power your applications with confidence.

FAQs

1. What defines a general purpose micro switch?

It is a type of switching device that is designed to be used in a broad variety of industrial and commercial applications, having consistent performance characteristics.

2. Why does IEC/EN 60947 compliance matter?

Compliance assures that a switch is compliant with the accepted safety and performance criteria with regard to low-voltage control equipment.

3. How does actuation force affect performance?

Proper actuation force ensures accurate triggering while minimizing mechanical wear and false signals.

4. Are sealed switches necessary for all environments?

Sealing is vital to surroundings that are in contact with dust or moisture or vibrations and enhances reliability and durability.

5. How does supplier selection impact switch reliability?

Trusted suppliers provide certified products, technical documentation, and long-term support, reducing operational risk.